The Versatility and Functionality of CNC Machines

In today's advanced manufacturing industry, CNC machines play a crucial role in improving productivity, precision, and efficiency. These computer-controlled machines have revolutionized the way we manufacture various components and products. From automotive to aerospace, healthcare to electronics, CNC machines have become an integral part of the manufacturing process. In this article, we will explore the various aspects of CNC machines and answer the question: what does a cnc machine do?

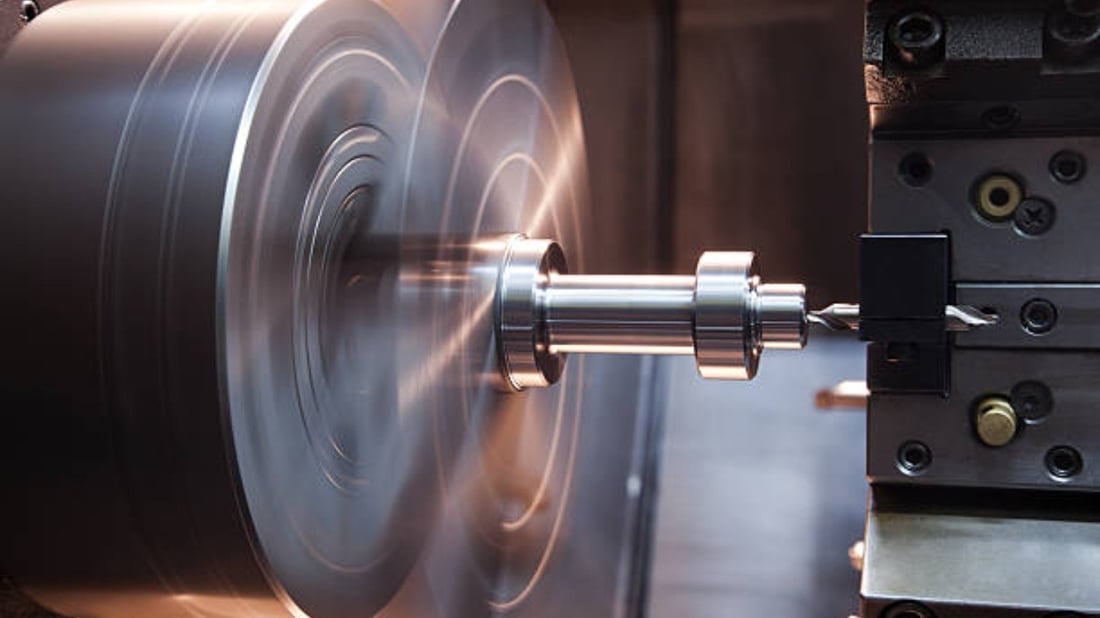

1. Precision Machining with CNC Machines

CNC machines excel at precision machining, offering unparalleled accuracy and repeatability. By following carefully programmed instructions, these machines can produce intricate geometries and tight tolerances, ensuring the highest quality of finished products. Whether it's milling, turning, grinding, or drilling, CNC machines can handle a wide range of machining operations with utmost precision.

2. Automation and Increased Productivity

One of the primary advantages of CNC machines is their ability to automate manufacturing processes. Once the initial setup is done, CNC machines can operate without constant human intervention. This automation leads to increased productivity as CNC machines can work 24/7, ensuring faster turnaround times and higher production rates.

3. Complex Shape Creation

With the help of advanced software and computer-aided design (CAD), CNC machines can effortlessly create complex shapes and contours. Whether it's a curved surface, intricate patterns, or multi-axis machining, CNC machines excel at transforming digital designs into tangible products. This capability opens up new possibilities for industries that require intricate and customized components.

4. Replication and Mass Production

When it comes to mass production, CNC machines shine. Once a design is programmed, CNC machines can effortlessly replicate it with absolute consistency. This ability ensures that each product is identical in dimensions and specifications, eliminating variations and defects that can occur in manual manufacturing processes. CNC machines are capable of producing large quantities of parts with minimal deviations.

5. Enhanced Efficiency and Time Savings

CNC machines offer significant time savings and improved efficiency compared to traditional manual machining. With their high-speed cutting capabilities and multiple tool changers, CNC machines can perform multiple operations in a single setup. This eliminates the need for manual tool changes and reduces setup times, ultimately resulting in faster production cycles and reduced lead times.

6. Increased Safety and Reduced Human Error

By automating manufacturing processes, CNC machines reduce the risk of human error and enhance workplace safety. With precise measurements, automated tool changes, and safety features, CNC machines can operate with minimal operator intervention. This minimizes the chances of accidents and injuries, ensuring a safer working environment for operators.

7. Prototyping and Rapid Iteration

For industries that heavily rely on prototyping and rapid iteration, CNC machines are invaluable tools. With their ability to quickly transform digital designs into physical prototypes, CNC machines enable designers and engineers to iterate and refine their designs at a faster pace. This accelerates the product development cycle and allows for quicker market entry.

8. Material Versatility

CNC machines can work with a wide range of materials, including metals, plastics, composites, and even wood. This versatility allows different industries to leverage CNC machines for their specific material requirements. Whether it's aluminum parts for aerospace applications or intricate plastic components for medical devices, CNC machines can handle the diverse material demands of various industries.

9. Continuous Improvement and Upgradability

CNC machines are not static entities; they can be continually improved and upgraded. As technology advances, manufacturers can enhance their CNC machines with the latest software updates, hardware improvements, and new capabilities. This ensures that CNC machines remain at the forefront of manufacturing technology, enabling businesses to stay competitive in a rapidly evolving industry.

10. Cost-Effectiveness and Return on Investment

Despite their initial investment cost, CNC machines offer long-term cost-effectiveness and a high return on investment. Their automation capabilities, reduced labor requirements, and increased productivity lead to significant cost savings over time. Additionally, the precision and consistency of CNC machining minimize material wastage and reduce the need for rework, further enhancing cost-effectiveness.